I was never a big fan of process flow maps. It seemed like such a tedious activity, which in my opinion didn’t do much but capture an already obvious process. But that all changed a few years ago. I was working with some Six Sigma Black Belts to develop a hands-on course on how to apply process control tools to the investment casting industry. We knew what we wanted to teach, we knew how we wanted to teach it, but we kept struggling with how to get where we wanted to go. After a few months of minimal progress, I mapped out the steps of the process we wanted the students to follow, identifying decisions that needed to be made and delays that could impact the flow.

What a game changer! This flow chart has become invaluable to students and to the instructors when we teach the class. Our instructors agree that mapping out the process was a turning point, and we often ask ourselves what took us so long to start using this tool, especially since it was a tool we were trying to teach the students to use.

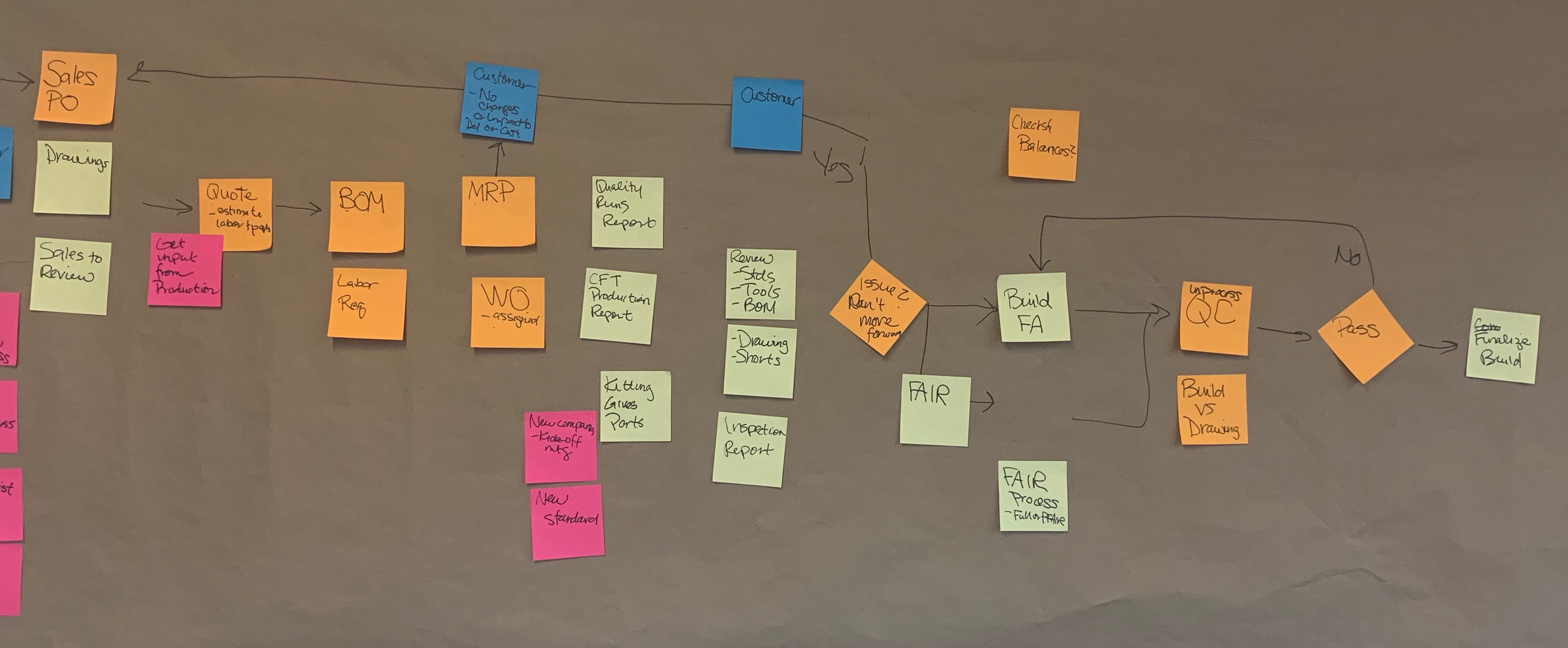

A few weeks ago, I was mapping out a process for a client and we identified some delays that could be avoided if we added some steps earlier in the process. We also identified ways to increase customer satisfaction by adding a few minor steps at strategic points in the process.

Are you looking for ways to increase throughput without adding resources? Try process flow mapping. This can highlight gaps, opportunities for improvement and non-value-added steps. By addressing those, you can reduce delays, improve consistency and increase capacity. If you want help getting started, send me an email! I’d love to help you!