by Julie | Apr 14, 2016 | Consulting, Employee Training, Interim Management, Management, Onboarding, Safety

THE START OF SOMETHING BEAUTIFUL

Starting a new job can be a little stressful. Meeting new people, learning new tasks and an adjusting to a new workplace culture. Can you think back to your first day with your current employer? Were you nervous? Excited? How were you greeted by your new peers? Was everyone expecting you?

Some employers seem burned out from the hiring phase – it is like a revolving door for new employees. Employees are hired and then they leave within a week or two resulting in more time and money spent on recruiting and training.

Without a doubt, hiring employees has gotten much more difficult in recent years. There is a shortage of skilled workers who have the workplace competencies needed in manufacturing. So, recruiting qualified candidates is much more difficult. (Check out this article on tips on recruiting the most qualified employees.)

But, once you have selected a qualified employee, you want to make them feel welcome. Have you thought about the first impression you give your new employee on their first day? Could you do more to let your new employees know you view them as a valuable member of your team? Here are few suggestions that could help in retaining your new employees:

- Interview current employees about what they thought about their first day, week or month with the company. What was their impression of how they were welcomed by the company? What is one thing they would like to see improved or implemented?

- Establish a mentor program so veteran employees can assist new hires assimilate into the culture.

- Create an employee based committee to assist in developing and instituting the onboarding process. You might even consider allowing them to participate in interviewing candidates.

- Provide a checklist for the hiring manager or supervisor so they can ensure the company is prepared for a new employee prior to the first day.

Establishing an onboarding program is an important part of retaining your work force (check out this blog for more information on onboarding). But, don’t overlook the importance of making a good impression on the first day. Making the employee feel welcome and helping them adjust to your culture can help retain a valuable new employee.

For more practical tips for manufacturing professionals to attract, train and retain your hourly workforce, go to www.keyprocessinnovations.com.

by Julie | Apr 7, 2016 | Consulting, Employee Training, Interim Management, Management, Onboarding, Safety

The goal in manufacturing is to SAFELY make an end product that meets customer specifications with the lowest cost possible. There is nothing more important than the safety of the employees. But even looking beyond the employee, having a strong safety culture also impacts your bottom line.

I recently met with a manufacturing professional who shared if you want to know if a company is profitable, ask them about their safety statistics. If they don’t know them off the top of their head or can’t find them quickly, they are probably struggling financially. Without a strong safety program, eventually the number of workplace accidents will start to climb.

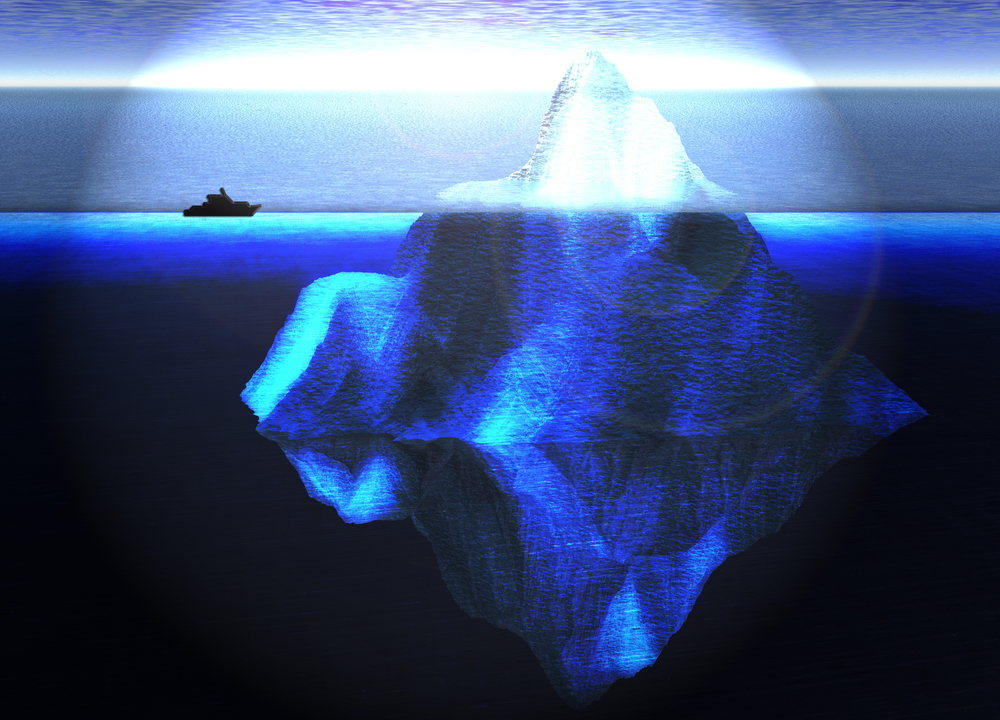

When thinking about workplace accidents, I imagine an iceberg with 20% above the water and 80% below the water. The cost of the accident is the part above the water including doctor/hospital bills, employee time-off, etc. But, the actual cost is what is under the water which includes increased insurance premiums, higher payroll and reduced plant productivity.

But, you don’t have to take my word for it. I found a lot of data that supports the relationship between a strong safety culture and profitability, including the following:

- A Liberty Mutual survey reports 61% of executives say $3 or more is saved for each $1 invested in work place safety (http://www.the-osha-advisor.com/CASE.html)

- Participation in OSHA’s Voluntary Protection Program saved one company $930,000 per year and the company had 450 fewer lost-time injuries than its industry average (http://www.asse.org/bosc-article-6/)

- According to the American Society of Safety Engineers, investment in health and safety programs can result in saving in workman’s comp claims, liability damages and litigation costs in addition to improvement in productivity and employee morale.

Providing a safe workplace for your employees is a win-win. It is good for the employees and good for your bottom line. If you believe your safety program needs a little work, there are a number of resources available online including an article I recently wrote on the importance of reporting near-misses.

For more practical tips for manufacturing professionals to attract, train and retain your hourly workforce, go to www.keyprocessinnovations.com.

by Julie | Mar 31, 2016 | Consulting, Efficiency, Employee Training, Interim Management, Management

WITH RIGIDITY OR FLEXIBILITY?

One of the reasons operators are trained to do a task the same way is to ensure uniformity and reduce process variability. However, this approach may not take into account how operators should react to slight process variations.

Yes, we want consistency from operator to operator but, we also want the operator to be aware of process fluctuations and adjust accordingly. One of the benefits of having an operator do a job rather than a robot is that they can observe the process. However, operators need to know what to do when slight changes are observed. Should they modify the process or stop production and notify management?

Some argue that operators should all do the same thing and not make any changes to the process. Others suggest that it is best to have operators aware of the overall process and the desired end result and then give them the flexibility to modify the steps based on their perceived best method. I see benefits and challenges with each of those approaches.

If operators are instructed to follow the process exactly as they were trained, the following questions come to mind:

- What is the impetus for making improvements to the process?

- What if a shift in the process impacts the final product?

- How do the operators provide input for a better method?

- Who decides whether this new method should be implemented?

If the operators have the flexibility to modify the process based on their perceived best method, I start to question:

- How do the operators know that their modification won’t impact product quality?

- Is their modification the most ergonomic method?

- Will other operators try the same modification but achieve a different result?

Regardless of the how you approach improvements to a process, it is critical that the operators have input. They work in the process on an ongoing basis and will detect subtle changes that might otherwise go unnoticed. Establishing a method for incorporating process improvements will go a long way towards reducing process variability.

For more practical tips for manufacturing professionals to attract, train and retain your hourly workforce, go to www.keyprocessinnovations.com.

by Julie | Mar 3, 2016 | Consulting, Employee Training, Interim Management, Onboarding

Over the past few months, I’ve been writing on a wide range of topics around how to attract, train and retain your hourly workforce. But, perhaps I should share why I find this topic so important.

First, it starts with safety. Nothing is more important than the health and safety of an employee. And, ensuring an employee is properly trained is a critical step in preventing workplace accidents.

Beyond that, here are some additional reasons why investing in training your employees is so important.

- The cost of replacing manufacturing employees ranges from 16 to 20% of their annual salary. That might not seem like a lot, but, depending on employee turnover, this cost can add up quickly.1

- Ten percent of the workforce over the age of 50 are expected to retire every year. Without a methodology to capture plant knowledge and a means to transfer it to newer employees, your business risks losing valuable information when a long-term employee retires.2

- It can take up to a year for an employee to reach peek job performance, however over 25% of employers do not have the necessary onboarding program to assist a new employee in gaining the necessary skills and knowledge during the first year.3 This results in lower job performance or higher employee turnover.

- Investing in employee training is a valuable tool for attracting and retaining employees. Employees, especially those from the Millennial generation, want opportunities to gain knowledge and learn new skills.

- Ensuring that operators are trained in multiple positions provides flexibility to the organization. This allows the plant to easily adjust to changes in work flow, varying product lines and changes to customer requirements.

- Employees who are properly trained are more familiar with the requirements of their position resulting in less scrap and increased productivity. Both of which will have a positive impact on your bottom line.

There is no doubt that having a robust operator training program will have an impact on your business. And the sooner you get started, the sooner you can help reap the benefits. If you know you need to improve your training program, but, you aren’t sure where to start, read this post titled It All Starts with One Step.

For more practical tips for manufacturing professionals to attract, train and retain your hourly workforce, go to www.keyprocessinnovations.com.

References:

1https://www.americanprogress.org/issues/labor/report/2012/11/16/44464/there-are-significant-business-costs-to-replacing-employees/

2 Pitt-Catsouphes & Matz-Costa, 2009

3http://www.tembostatus.com/blog/how-career-training-can-reduce-employee-turnover

by Julie | Feb 25, 2016 | Consulting, Efficiency, Employee Training, Interim Management, Management

A lot of people claim to have a “6th Sense” when assessing a situation. But, when it comes to making a business investment, having a benchmark and being able to quantify improvements is essential. Making process improvements in your process may require an investment in financial, personnel or temporal resources and in order to justify the investment, you may need more than a sense in order to get the necessary support.

No matter what problem solving methodology used within your plant, most start by defining the problem. And part of this initial step includes identifying measures of process performance and establishing a baseline. An often overlooked reason for this step is to ensure the gains are sustained after improvements have been implemented.

Listed below are some metrics that can be used to measure process performance.

- First Pass Yield. This measures the number of good units produced against the total number of units produced. Depending on your process, this measurement can be broken down by department, by machine or by operator.

- Value Added vs Non-Value Added Time. Gathering data for this can be done via Value Stream Mapping or through Time Observations. From these studies, value and non-value added steps can be identified. As non-value added time is reduced, process output should increase.

- % Uptime. By defining % Uptime as outlined below, this measurement also takes into account set-up, changeovers, loading, unloading, idle time, breaks, cleaning, maintenance, etc.

% Uptime = (Value Added Time) x 100

(Operating Time)

- Process Capability, Cp or Cpk. In order for a process to be considered capable, it needs to be stable. Process stability means having consistent centering around the mean and predictable variation.

As you look towards making improvements in your process, try to pick a metric currently in use (or one that should be implemented) and use that to establish a baseline. Then utilize that metric to show areas which need improvement. Additionally after changes are made, data is available to document the improvement and provide a metric to sustain the gains.

For more practical tips for manufacturing professionals to attract, train and retain your hourly workforce, go to www.keyprocessinnovations.com.

by Julie | Feb 11, 2016 | Consulting, Employee Training, Interim Management, Management

The task of operator training is typically delegated to the department supervisor or lead. Rarely, if ever, is the supervisor or lead given the proper tools to be an effective trainer. And since the supervisor is also evaluating the operator’s performance, the feedback loop on training effectiveness may be lost. Being an effective trainer goes beyond knowing the material. It requires an ability to communicate in such a way that the trainee can learn the required information.

Listed below are some suggestions on how ways to improve the effectiveness of your training.

- Ensure the trainer has the necessary skills to conduct operator training. Check out this blog for what I consider the necessary skills to be an effective trainer. In some cases, it may be necessary to delegate training to an individual who may not be a lead/supervisor in order to ensure the training is as effective as possible.

- Periodically observe the training being conducted and provide feedback for the trainer.

- If possible, also have the trainee provide feedback on the trainer.

- Make sure there is some way to demonstrate the operator has learned the necessary information in order to do this task on his or her own. This can be through a verbal test, written quiz or a demonstration.

- Invest in some “train the trainer” training so the supervisors and/or lead can develop their skills as a trainer.

Creating an environment of learning can go a long way towards improving the performance of your plant. Increasing the skills of your trainers will help operators learn faster, be more engaged and ultimately improve the bottom line. And isn’t that the name of the game?

For more practical tips for manufacturing professionals to attract, train and retain your hourly workforce, go to www.keyprocessinnovations.com.

by Julie | Feb 4, 2016 | Consulting, Employee Training, Interim Management, Management

It is my belief and experience that operators don’t want to do a bad job. They want to do what is asked of them and do it to the best of their ability. But, we still see instances where operators aren’t following the established procedures. And when that happens, we need to understand why so steps can be taken to address the issue(s).

If you find yourself asking why your operators aren’t following procedures, here are some questions you can ask to help get to the root cause of the problem.

Were the instructions clearly defined? It may be clear in your mind how things need to be done, but, without providing detailed instructions, the task may be left up to the operator’s interpretation.

Are there visual reminders as to what needs to be done? Don’t rely on an operator to remember all the details of a particular process. Make procedures available for reference or post standard work on the floor to remind operators of the proper way to do a particular task.

Is there a better way to do it? Operators who do a particular task on a repetitive basis may have a more efficient way. Making yourself open for improved techniques will make the operators more likely to share their ideas, rather than doing it their way when you aren’t around.

Do the operators need refresher training? No matter the task, after a certain amount of time, an operator might need a little refresher training. The frequency of the refresher training could be impacted by the availability of visual reminders.

Have the operators been properly trained? There are times when the training wasn’t sufficient for the operators. If that proves to be the case, then it may be necessary to assess the effectiveness of your training and/or the trainer.

In the next blog, we will look at ways to assess the effectiveness of your trainer.

For more practical tips for manufacturing professionals to attract, train and retain your hourly workforce, go to www.keyprocessinnovations.com.

by Julie | Jan 13, 2016 | Consulting, Employee Training, Interim Management

After expending company resources to find and hire a great new employee, have you thought about what the employee will need to know in order to be successful in your organization?

A report from the Society of Human Resource Management found that half of all hourly employees leave within the first 120 days. However, another study completed by the Wynhurst Group found that having an effective onboarding process can increase employee retention by 58 percent, and improve employee performance by 11 percent.

Wikipedia defines onboarding as the mechanism through which new employees acquire the necessary knowledge, skills, and behaviors to become effective organizational members and insiders.

Here are some best practices to establish an effective onboarding process for your company:

- Establish an onboarding outline. This outline may vary for each position but should be adapted for each specific candidate. Key aspects include:

- Expectations of the job;

- Explanation of how their job contributes to the company’s strategic goals;

- Job specific training with key personnel assigned to assist with the training;

- Company focused training so the employee understands the business, including the values and culture;

- Performance goals;

- Feedback.

- Be prepared for the employee prior to her first day. What kind of a message does it send when you aren’t prepared for the employee on his/her first day? Paperwork should be prepared, schedule established and team members notified. Having a new employee standing around waiting for you doesn’t send a welcoming message.

- Make onboarding a two-way street. Giving some responsibility to the employee during onboarding helps them gain ownership in the process. For example, you could have an employee list the areas where he feels he needs further training or exposure.

- Establish a calendar for onboarding. What specifically does the company need to do in the 1st day, week, month and beyond? What specifically is the employee responsible for? One company requires that the employee and supervisor set goals during the first 30 days which must be completed prior to the 90-day review.

- Schedule one-on-one meetings on a consistent basis. During these meetings, both parties should be open to feedback, suggestions and questions.

- Extend the onboarding process beyond 90 days. As the employee becomes a contributing member of the workforce, shift the conversation towards employee development and advancement.

Considering how difficult it is to find qualified employees, doesn’t it make sense to have an effective onboarding process to ensure that you retain and develop the ones you have?

For more practical tips for manufacturing professionals to attract, train and retain your hourly workforce, go to www.keyprocessinnovations.com.

by Julie | Dec 3, 2015 | Consulting, Employee Training, Interim Management

Over the Thanksgiving holiday, my husband and I flew back to Wisconsin to be with family. Unfortunately, Chicago was experiencing its first big snow storm of the season and flights into the airport were being delayed. So, we sat in Portland waiting for our flight to take off. We kept hearing we would get flight updates in an hour, then the hour came and it was another flight update in 30 minutes. The airline handled the situation well and despite being a weather delay, they even handed out food vouchers as we waited.

After four hours, Chicago Air Traffic Control lifted the ground stop and gave our flight a departure time. So, we all line up and started boarding the aircraft. In the middle of boarding, the crew told us to stop, gather our belongings and get off the plane. Apparently, the pilots had timed out and left the airport, leaving us with no one to fly the plane. So, we all de-planed feeling rather frustrated with the airline.

I heard one traveler ask the flight attendant why the ground crew had us start boarding when they didn’t have a pilot. Her response was that there was no communication between the ground crew and pilots only between the ground crew and the flight attendants.

As we waited for a pilot, I thought about how a simple process of communication between the pilots and ground crew could have avoided the frustration of having passengers deplane. And all the good will that the airline earned during the weather delay was erased due to poor internal communication.

As you look at your internal processes, do you see areas where enhanced communication could improve your customer experience? Could improved internal processes protect your customer’s good will that you try so hard to earn?

Looking for some ideas on how to improve your internal processes? Let’s talk – I know I can help!