by Julie | Jan 13, 2016 | Consulting, Employee Training, Interim Management

After expending company resources to find and hire a great new employee, have you thought about what the employee will need to know in order to be successful in your organization?

A report from the Society of Human Resource Management found that half of all hourly employees leave within the first 120 days. However, another study completed by the Wynhurst Group found that having an effective onboarding process can increase employee retention by 58 percent, and improve employee performance by 11 percent.

Wikipedia defines onboarding as the mechanism through which new employees acquire the necessary knowledge, skills, and behaviors to become effective organizational members and insiders.

Here are some best practices to establish an effective onboarding process for your company:

- Establish an onboarding outline. This outline may vary for each position but should be adapted for each specific candidate. Key aspects include:

- Expectations of the job;

- Explanation of how their job contributes to the company’s strategic goals;

- Job specific training with key personnel assigned to assist with the training;

- Company focused training so the employee understands the business, including the values and culture;

- Performance goals;

- Feedback.

- Be prepared for the employee prior to her first day. What kind of a message does it send when you aren’t prepared for the employee on his/her first day? Paperwork should be prepared, schedule established and team members notified. Having a new employee standing around waiting for you doesn’t send a welcoming message.

- Make onboarding a two-way street. Giving some responsibility to the employee during onboarding helps them gain ownership in the process. For example, you could have an employee list the areas where he feels he needs further training or exposure.

- Establish a calendar for onboarding. What specifically does the company need to do in the 1st day, week, month and beyond? What specifically is the employee responsible for? One company requires that the employee and supervisor set goals during the first 30 days which must be completed prior to the 90-day review.

- Schedule one-on-one meetings on a consistent basis. During these meetings, both parties should be open to feedback, suggestions and questions.

- Extend the onboarding process beyond 90 days. As the employee becomes a contributing member of the workforce, shift the conversation towards employee development and advancement.

Considering how difficult it is to find qualified employees, doesn’t it make sense to have an effective onboarding process to ensure that you retain and develop the ones you have?

For more practical tips for manufacturing professionals to attract, train and retain your hourly workforce, go to www.keyprocessinnovations.com.

by Julie | Jan 7, 2016 | Consulting, Employee Training

WELCOME TO 2016! If you are like most people, you pushed a number of issues into the new year and now is the time to address them. One of the issues that tends to be pushed into January is employee hiring. Do you have a few job openings and not a lot of prospects to fill them?

Recruiting for employees, especially hourly employees can be very frustrating. It is getting increasingly difficult to find employees with the necessary skills to work in a manufacturing environment.

Here are 7 tips that will help you recruit the most qualified employees.

- Don’t limit recruiting to just when there is an opening. The chances of finding a highly qualified employee at the exact moment that you have a need are much lower than if you recruit on a continual basis. You might not have an immediate need to hire, but, if someone with your desired skills set is available, it may be best to hire them and make room in the organization. If you wait until there is an opening, your highly qualified candidate will probably have found another position.

- Does your job description sell the position to your desired candidate or does it read like a legal document? Consider including not only the skills needed to do the job but also some interesting challenges that a candidate might face. You might want to reach out to a member of your marketing team or a “creative” for some input on wordsmithing.

- Ask your current employees, especially the good ones. If you have an employee who has had a positive impact on your organization, chances are that he/she has friends that may be looking for a job. Offering an incentive to the employee is an option to help attract new employees.

- Don’t limit your hiring practices to regular business hours. Most qualified applicants have another job and may need to apply when they are not at work. A few options for applicants to reach you off-hours include an answering service, a job line or even applying on-line.

- Use technology to help attract employees. Let’s face it, most people look for jobs on-line. And if you aren’t listing your job on-line, you aren’t being seen. Depending on the type of employee you are searching for, there are plenty of websites to list your openings or you can also list your openings on your company’s website.

- Does your company’s on-line presence attract the right type of employees? A tech savvy applicant is going to Google your company – what will they find? A website doesn’t just give you credibility with your customers, it also provides credibility with your current and future employees.

- Get involved in the community. There are plenty of ways to be involved in the local community and through those activities, you can get to know the people in the community better. Whether you serve on a board, volunteer at a school or join a local professional organization, you are building and strengthening relationships. These relationships may become a source of referrals.

These tips may not help you fill the openings you have right now, but, if you start now, you will already have qualified candidates in your pipeline before the need arises.

For more practical tips for manufacturing professionals to attract, train and retain your hourly workforce, go to www.keyprocessinnovations.com.

by Julie | Dec 23, 2015 | Employee Training, Safety

Over the past few weeks, the Pacific Northwest has experienced a deluge of rain, even setting some records for daily rain fall and consecutive days with measurable rain. As you can imagine, the traffic has been dreadful with landslides, flooding and lots of standing water on the roads. As I was trying to make it to an appointment last week, I started to think about some of the near misses I have experienced driving in the rain and I used extra caution to make sure I was prepared for those situations.

Being aware of near misses is an important part of building a safety culture. Did you know that for every accident, there are upwards of 30 near misses? And research shows that if you identify and address those near misses, the number of accidents can be reduced.

So, here are some tips on how to address those near misses:

- Have each employee report a near miss at some specified frequency, maybe every week or every month. The reporting near misses will increase the employees awareness of looking for unsafe practices or situations.

- Offer incentives for employees who report near misses.

- Treat every near miss as you would an accident. That includes investigation, determination of root cause and implementation of appropriate controls.

- Share near misses and lessons learned with employees.

As you move into 2016, perhaps this is the year to implement some changes to your safety program. And what could be a better gift to your employees than the gift of safety?

by Julie | Dec 3, 2015 | Consulting, Employee Training, Interim Management

Over the Thanksgiving holiday, my husband and I flew back to Wisconsin to be with family. Unfortunately, Chicago was experiencing its first big snow storm of the season and flights into the airport were being delayed. So, we sat in Portland waiting for our flight to take off. We kept hearing we would get flight updates in an hour, then the hour came and it was another flight update in 30 minutes. The airline handled the situation well and despite being a weather delay, they even handed out food vouchers as we waited.

After four hours, Chicago Air Traffic Control lifted the ground stop and gave our flight a departure time. So, we all line up and started boarding the aircraft. In the middle of boarding, the crew told us to stop, gather our belongings and get off the plane. Apparently, the pilots had timed out and left the airport, leaving us with no one to fly the plane. So, we all de-planed feeling rather frustrated with the airline.

I heard one traveler ask the flight attendant why the ground crew had us start boarding when they didn’t have a pilot. Her response was that there was no communication between the ground crew and pilots only between the ground crew and the flight attendants.

As we waited for a pilot, I thought about how a simple process of communication between the pilots and ground crew could have avoided the frustration of having passengers deplane. And all the good will that the airline earned during the weather delay was erased due to poor internal communication.

As you look at your internal processes, do you see areas where enhanced communication could improve your customer experience? Could improved internal processes protect your customer’s good will that you try so hard to earn?

Looking for some ideas on how to improve your internal processes? Let’s talk – I know I can help!

by Julie | Nov 4, 2015 | Consulting, Efficiency, Employee Training, Interim Management

Business vector designed by Balasoiu – Freepik.com

As an athlete, I have some recurring injuries that flare up when training for an event. Since my issues were always on my left leg, I often joked that I should just cut off my left leg and grow back a new one, preferably without these nagging injuries.

While that might seem like a far-fetched idea, I had client who was having systemic issues with their workforce and made the decision to fire a majority of the employees and then hire new employees. In their mind, this would resolve the inherent cultural issues and allow them to hire operators with a skill set that would be better suited to support the new direction of the company.

What appeared to be overlooked was the amount of time required for an operator to master a specific job function. How would a new employee learn those skills if they weren’t taught by someone who possessed them? How long would it take to develop those skills?

Here is what I believe to be true about operators – they don’t purposely decide to do a bad job. People inherently want to take pride in their work. So, if they aren’t following the process, the logical question is why?

So, we started asking questions, including:

- Do the operators know and understand what is expected of them?

- Do the operators receive feedback on their individual performance and the performance of the department?

- Are there established procedures to follow?

- Have the operators been trained on the procedure(s)?

After reviewing the responses from the questions above, I proposed a different approach. Start by training the employees on what is expected of them and put the systems in place to ensure the training is reinforced. This isn’t as drastic as hiring all new employees, but, in the end, the results are much more sustainable.

So, just like my nagging sports injury, we identified the root cause of the problem and strengthened the areas that were causing issues. And over time, the organization became much stronger. Do you have some issues that are keeping your organization from operating at maximum efficiency? Let’s connect and see if we can work together to make your organization healthy and happy.

by Julie | Jan 18, 2013 | Employee Training

How much time is spent thinking about slurry viscosity control? My guess is, not much. It seems to be a necessary evil of running a shell room, but not an area where we spend a lot of time.

What is the impact of the slurry viscosity being out of range? Operating outside of the targeted range could result in variations in shell thickness. If the back-up viscosity is running thick, then the mold weight could increase by up to 10%, especially in the later dips. If the viscosity is below the lower limit that could result in a thinner slurry layer and potential shell failures including run-outs or surface finish defects.

What is viscosity and why do we measure it? Viscosity is the measurement of a fluid’s resistance to flow, in our case, the slurry. A number of factors can impact the slurries viscosity, including liquid content (silica, water and polymer), particle size of the flour and temperature, to name a few.

Assuming a slurry is within specification for its key parameters, i.e. percent silica, temperature and refractory solids, the viscosity measurement is a value used in this industry which identifies how much slurry will be deposited on the wax pattern and/or previous dips. The ideal viscosity for slurry is dependent on the type of slurry and the part configuration. This is normally set by shell room management or by the supplier. The operator’s responsibility is to maintain the slurry within the designated range.

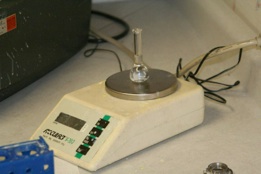

Viscosity is typically measured using a viscosity cup or in some instances a viscometer. Most commercial foundries using a viscosity cup establish a 2-second range and try to maintain the viscosity within that range.

However, the different techniques used by operators while measuring viscosity can have an impact on the value they record.

- To Rinse or not to Rinse: If the cup is stored in water, is it rinsed with slurry prior to taking a reading?

- Why Stop at One Reading: How many readings should be taken prior to recording?

- Location, Location, Location: Where in the tank is the slurry most uniform?

- Blink or ¼” stream: Are the operators looking for a blink or a stream break? If a stream break, what distance from the cup?

How you measure viscosity isn’t as important as ensuring that all your operators are doing it the same way. The amount of time it takes for a slurry to flow through a cup is relative, not absolute. But, you want your operators to minimize the variation.

Some operators are very comfortable taking viscosity readings. Inevitably, there will be an operator who is not comfortable measuring viscosity and his readings will be significantly different from the other operators. If the slurry is being adjusted based on this operator’s reading, the slurry could be adjusted to be out of the range.

Once you understand how viscosity control is being managed, you can start to address the variations. Training them not only on the viscosity procedure but also on why viscosity is important can go on long way towards improving viscosity control.

The final step is to continue to follow up on a regular basis to ensure that the operators are following the established procedure and reinforce the importance of viscosity control.

by Julie | Nov 8, 2012 | Employee Training

The mold cleaning and etch process seems to be one of those forgotten parts of the investment casting process. It isn’t like the parts look any cleaner when they come out of the tank. So, how important is this process to the overall process?

The purpose of the pattern cleaner is two fold – to clean the wax and to etch the surface to make it easier for the prime to hold onto the wax. While some foundries don’t try to etch the wax, almost all foundries recognize the need to clean the wax. A robust process prevents issues with slurry adhesion and coverage.

Like almost everything else in the precision investment casting process, not monitoring the process closely can lead to variability. So, here are few of the most common issues I have experienced when it comes to the etch process:

- Inconsistent immersion times. Not enough can cause issues with the adhesion of the wax to the prime. Too much can cause a rough wax surface.

- Wax build-up in the etch. This can reduce the efficacy of the pattern cleaner.

- Dirty rinse water. Not changing the rinse water impacts the effectiveness of the rinse. It is also a potential source of bacteria.

So, some good practices when it comes to the etch process, include:

- Post the etch time on or near the tank. In addition, put a clock in the area so the operator can verify the immersion time.

- Skim the etch tank prior to starting dipping. This is especially true if air is being bubbled into the tank.

- Check both the etch and rinse tanks for bacteria. This can be carried into the prime slurry causing stability issues.

- Identify a test that provides information on the efficacy of the cleaner. There have been a number of tests identified by the different suppliers. Find one that you are comfortable with and also provides meaningful data.

If you have some questions regarding your pattern cleaning process, don’t hesitate to give me a call or email me at julie@keyprocessinnovations.com. I can answer your questions and get you on your way towards a more robust process.

by Julie | May 23, 2012 | Employee Training

Stability of colloidal silica is important for the health and performance of an investment casting slurry. pH is one indicator as to the stability. Conductivity is another important indicator and information on that topic can be found here.

Accurate measurement of pH is critical. I have received numerous phone calls from customers stating that the pH of the slurry is 11.0 or even higher. If the pH of a silica-based sample is above about 10.5, the silica particles can begin to dissolve. Since the slurry additives typically lower the pH, a reading of 11.0 could indicate issues with your meter.

If you are unsure if the pH is giving accurate results, check the pH of the incoming colloidal silica and compare the reading to the supplier’s certification.

If you are unsure if the pH is giving accurate results, check the pH of the incoming colloidal silica and compare the reading to the supplier’s certification.

The trending of the pH over time is as important, if not more important, than an absolute value. For example, a pH of 9.2 could be a reason for concern. However, if the pH has been slowly drifting down to 9.2 and then settling there, the slurry stability may be fine. Checking conductivity is another way to confirm the health of the slurry.

Care of a pH meter will vary by manufacturer. Take some time to review the manual and ensure that the proper calibration and maintenance procedures are followed.

If you are still unsure of your readings, feel free to contact me for more information at Julie@keyprocessinnovations.com.

by Julie | May 16, 2012 | Employee Training

One of the most common slurry tests performed for investment casting slurries is SiO2 percentage. Insufficient concentration of SiO2 in the slurry creates a weak shell. However, having too high a concentration can also cause a weak shell while potentially gelling the slurry.

The two common methods for measuring binder solids are volumetric and through the use of a densitometer. For this discussion, we will focus on the volumetric method.

Ensure that the sample has been spun long enough to remove the refractory particles from the supernate (liquid on the top of the solids). If this isn’t done, the results will be inaccurate, regardless of the test method utilized.

Of the two methods, the volumetric procedure can lead to the most variability. This variability can come from the following:

1. Uncalibrated flasks

2. Dirty flasks

3. Fill line identification

Most foundries make the mistake of assuming that a 10 ml volumetric flask filled with water will weigh10 grams. Making this assumption could lead to inaccurate results. However, if you compound this error with a dirty flask and the results will be even further off. I have seen the percentage of silica be off by up to 3 percentage points by not calibrating a dirty flask.

Most foundries make the mistake of assuming that a 10 ml volumetric flask filled with water will weigh10 grams. Making this assumption could lead to inaccurate results. However, if you compound this error with a dirty flask and the results will be even further off. I have seen the percentage of silica be off by up to 3 percentage points by not calibrating a dirty flask.

The other challenge that operators sometimes face is knowing how to locate the meniscus. By going through the calibration process, this can help operators understand how a slight difference in the fill line can impact the results.

The ICI has outlined a procedure on how to calibrate your flasks every time the test is performed. Or, if you have questions, feel free to contact me for more information at Julie@keyprocessinnovations.com.