Communication: A Key to Retaining Customer Good Will

Over the Thanksgiving holiday, my husband and I flew back to Wisconsin to be with family. Unfortunately, Chicago was experiencing its first big snow storm of the season and flights into the airport were being delayed. So, we sat in Portland waiting for our flight to...

Addressing Your Nagging Injuries Through Training

As an athlete, I have some recurring injuries that flare up when training for an event. Since my issues were always on my left leg, I often joked that I should just cut off my left leg and grow back a new one, preferably without these nagging injuries. While that...

What’s Your Mantra?

During a recent assignment, I was the acting Interim Director of Manufacturing while an executive was putting a new management team in place. This was a difficult time for the company – scrap was at an all time high, a manager with almost 20 years of knowledge had...

The Importance of Viscosity Control

How much time is spent thinking about slurry viscosity control? My guess is, not much. It seems to be a necessary evil of running a shell room, but not an area where we spend a lot of time. What is the impact of the slurry viscosity being out of range? Operating...

New Year’s Resolutions Or Efficient New Year?

I don’t know about you, but, I tend to steer way from New Year’s Resolutions. I haven’t been all that great about keeping them and so, instead of motivating me, they tend to discourage me. But, from a business perspective, the new year brings opportunities to find...

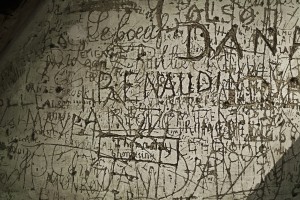

Leave a Mark: Etch and Clean the Wax Molds

The mold cleaning and etch process seems to be one of those forgotten parts of the investment casting process. It isn’t like the parts look any cleaner when they come out of the tank. So, how important is this process to the overall process? The purpose of the...

Tis the Season: Managing Shell Drying during Summer

I love this time of the year when the warm weather finally appears! The plants are growing and life is good! However, it is also the time of the year when shell drying related issues start to creep up! So, I thought I’d share a few items to check if you start to see...

Answer a Question with a Question: Slurry Testing Frequency

I am frequently asked how often should I test my slurry? I know you shouldn’t answer a question with a question, but what about a series of questions? ✓ How often do you have to make adjustments to your slurry? ✓ Are the adjustments with water, binder or a mixture of...

Hitting the pH Target

Stability of colloidal silica is important for the health and performance of an investment casting slurry. pH is one indicator as to the stability. Conductivity is another important indicator and information on that topic can be found here. Accurate measurement of...